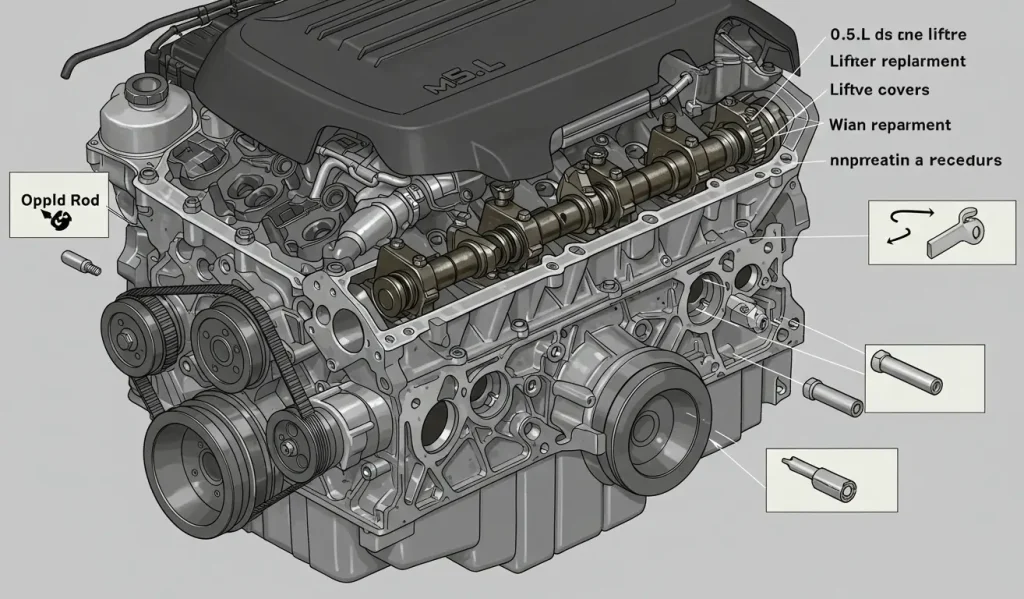

Easy 5.3 Lifter Replacement Without Removing Head: A Detailed DIY Guide

Replacing lifters in your 5.3L engine can sound like a nightmare, especially when you’re told the cylinder heads need to come off. That means more time, more tools, and often, more money. But what if you could skip all that?

Yes, you heard it right — you can replace the lifters on a 5.3 engine without removing the head. This technique is growing in popularity among mechanics and DIY gearheads alike. It offers a faster, cleaner way to address lifter issues while keeping the engine mostly intact.

In this comprehensive guide, we’ll walk you through the entire process, from preparing your work area to installing new lifters — all without removing the heads.

Understanding the Role of Lifters in a 5.3 Engine

What Do Lifters Actually Do?

Lifters, also known as hydraulic tappets, are a vital component of the valve train. They sit between the camshaft and the pushrods. When the camshaft rotates, it pushes the lifters, which then move the pushrods, causing the rocker arms to open the valves.

Why Do Lifters Fail?

Lifters can fail due to:

- Lack of lubrication

- Dirty oil or sludge buildup

- Excessive wear over time

- Collapse of internal components

A failed lifter causes ticking noises, misfires, or even cylinder deactivation issues in Active Fuel Management (AFM) systems common in many GM 5.3 engines.

Can You Really Replace Lifters Without Removing the Head?

Yes, But There’s a Catch

In some engine configurations, especially those with AFM, replacing lifters without removing the cylinder heads is indeed possible — but only in specific scenarios:

- If the issue is with non-AFM (standard) lifters.

- If access to the lifters is possible through the valley cover or by removing the pushrods and rocker arms.

This technique requires special tools, precision, and patience, but it saves hours of labor and eliminates the need to replace expensive head gaskets.

Preparing Your Vehicle for Lifter Replacement

Safety First

Before turning a wrench, make sure to:

- Park on a flat, well-lit surface

- Allow the engine to cool

- Disconnect the battery

- Wear gloves and safety glasses

Gather the Right Tools

- Torque wrench

- Socket and ratchet set

- Magnetic pickup tool

- Lifter removal tool (magnetic or hook style)

- Clean rags

- Valve cover gasket

- Engine oil

- Shop towels and containers for draining fluids

Remove Key Components

Start by:

- Removing the intake manifold and throttle body

- Taking off the valve covers

- Disconnecting ignition coils and pushrods

- Draining coolant if necessary

Step-by-Step Guide to Replace 5.3 Lifters Without Head Removal

Step 1: Gain Access to Lifters

- Start by removing the intake manifold and valve covers.

- Carefully take out the rocker arms and pushrods.

- Use a flashlight to look into the lifter bore via the pushrod holes.

Step 2: Rotate the Engine

Manually rotate the crankshaft so that the cam lobes are not pressing on the lifters you want to remove. This relieves pressure, making extraction easier.

Step 3: Extract Old Lifters

- Use a magnetic lifter removal tool or a custom hook tool.

- Slowly wiggle and pull the lifter straight up.

- Avoid scratching the lifter bore during removal.

Step 4: Clean the Bores

- Spray a non-residue solvent into the bores.

- Use lint-free cloths or swabs to remove old oil, sludge, or debris.

- Inspect the bore walls for scoring or damage.

Step 5: Lubricate and Install New Lifters

- Soak new lifters in clean engine oil.

- Lubricate the bore lightly with engine assembly lube.

- Insert the new lifters using your tool, ensuring they seat properly.

Step 6: Reassemble

- Reinsert the pushrods and rocker arms.

- Re-torque them to manufacturer specifications.

- Reinstall valve covers, intake manifold, and reconnect all hoses and wiring.

Step 7: Final Checks

- Reconnect the battery.

- Start the engine and listen carefully for any odd noises.

- Check for oil leaks or loose connections.

- If all seems well, take it for a short test drive and monitor engine behavior.

Tips and Tricks for a Smooth Repair

🛠 Use a Magnetic Lifter Tool

This tool is worth its weight in gold for pulling lifters without disassembly.

🧹 Keep Your Workspace Clean

Prevent contamination by working in a dust-free area and covering exposed parts.

🧾 Label Everything

Use masking tape or zip-top bags to label bolts and small parts during removal.

🔧 Use Torque Specs

Don’t guess — always refer to the GM manual or a trusted database for torque values.

🛢 Change the Oil

After completing the job, change the oil and filter to remove any debris.

Pros and Cons of This Method

✅ Pros

🔹 Saves Time

Avoids the lengthy process of removing cylinder heads and related components.

🔹 Cost Effective

No need to buy head gaskets or pay for head machining.

🔹 Less Downtime

Ideal for home mechanics working on a weekend project.

❌ Cons

🔸 Limited Access

You may not be able to reach all lifters without pulling the heads, depending on the issue.

🔸 No Head Inspection

This shortcut means you’re not inspecting valves or combustion chambers.

🔸 Higher Risk of Mistakes

Requires precision and care — there’s less margin for error.

When You Should Remove the Head

Sometimes you have no choice:

- If you’re replacing AFM lifters, which are deep in the block

- If you find metal debris in the oil or lifter damage

- If compression issues suggest valve damage

In these cases, full disassembly and inspection are necessary for a proper fix.

Final Thoughts

Doing a 5.3 lifter replacement without removing the head is not just a clever workaround — it’s a practical, efficient method for the right situation. While it won’t work in every case (especially for AFM-related issues), it’s a powerful tool in the hands of a capable DIYer.

Always assess the condition of your engine, gather the proper tools, and approach the job with patience and organization. When done correctly, this method can restore your engine’s performance, silence annoying ticks, and save you hundreds of dollars in labor.

If you’re new to engine repair, take your time. Watch tutorials, read your service manual, and don’t be afraid to ask for help. You’ve got this — and your 5.3 engine will thank you for it.